The ACE team is composed of two CNRS researchers and two professors/researchers, physical chemists, whose research is related to the problems of nuclear materials and their behavior under extreme conditions and at interfaces. Indeed, whatever the type of nuclear reactor envisaged (fission, fusion) and throughout the nuclear fuel cycle, from upstream to downstream through reactor operation, materials undergo strong chemical and structural modifications due to extreme conditions of temperature and irradiation. It is crucial to understand the fundamental mechanisms that govern the damage of these materials and thus modify their properties. The stakes associated with this research are major, particularly in terms of safety.

All generations of reactors are concerned, such as the first generation of nuclear reactors called UNGG where nuclear graphite was used as a moderator, but also core materials (fuel, structural steel, etc.) of current second and third generation reactors (PWR and EPR) as well as the liquids used or envisaged in the process of reprocessing nuclear waste. This research also concerns carbide-type ceramics envisaged for a fourth generation of reactors whose technology will be a break with the current PWR and EPR. In addition, the impact of radiolysis at interfaces is also a subject of interest.

The approach consists in subjecting these materials to ionizing radiation as well as to thermal treatments (up to 2000°C) and then to characterize the evolution of several physicochemical, mechanical or structural properties of these materials. This approach makes it possible to exacerbate the effects visible in reactors at the laboratory scale in reasonable times. In parallel, an approach by atomistic modeling allows a better understanding of the fundamental mechanisms that govern the effects of irradiation.

The ACE Group’s activities mainly concern the behaviour, under extreme temperature and irradiation conditions, of ceramic (UO2, B4C) or metallic (steels) materials used in nuclear reactors. Another aspect concerns the chemistry of lanthanides and actinides in ionic liquids, in particular for their selective separation during the reprocessing of spent nuclear fuel. Our work is mainly carried out within the GdR SciNEE (Nuclear Sciences for Energy and the Environment) and the CNRS multidisciplinary NEEDS programme (Nuclear, Energy, Environment, Waste, Society). They are also the subject of collaborations with the main players in the nuclear industry (EDF, IRSN).

- I. Behaviour, under extreme temperature and irradiation conditions, of nuclear ceramics

- II. Tribocorrosion of metal alloys under irradiation

- III. Study of ionic liquids for the separation of actinides and lanthanides

I. Behaviour, under extreme temperature and irradiation conditions, of nuclear ceramics

Two types of ceramic materials are currently being studied: UO2 et B4C. Uranium dioxide is the nuclear fuel for pressurized water reactors (PWRs), while boron carbide is a material used in the control rods of current reactors and is widely considered for the moderator of fourth-generation reactors, whose technology is based on the use of fast neutrons.

The aim is to characterise the behaviour of fission or activation products in these materials under normal or accidental reactor conditions, i.e. under the effect of temperature and irradiation.

1.1 Study of thermal migration of fission products in UO2 et UO2+x

Pressurized water type nuclear reactors (PWRs) are fuelled with UO2 ou (U,Pu)O2 fuel (called MOX) in which energy is produced by fission. During normal reactor operation, this fuel is subjected to high temperatures (up to 1000°C) and to the irradiation induced in particular by the formation of fission products. The presence of the latter also leads to microstructural modifications by forming bubbles, precipitates or solid solutions in the fuel.

The release of fission products into the environment in the event of an accidental reactor sequence is a major concern. Improving reactor safety requires the ability to assess the quantities, speciation and release kinetics of these fission products (FPs) in order to model their behaviour under different possible scenarii. For this purpose, it is necessary to have a detailed understanding of the behaviour of FPs according to different parameters (temperature, irradiation, interactions with other fission products, etc.).

TEM micrograph of cesium bubbles after annealing a UO2 pellet at 1600°C

Our studies conducted in collaboration with ORANO (ex-AREVA), IRSN and JRC Karlsruhe aim at evaluating the diffusion coefficients of fission products Xe, Mo et Cs in UO2 and identifying their migration mechanisms under the effect of high temperature (1000-1600°C), oxidizing atmosphere and/or ion irradiation. Stable isotopes of the fission products are introduced into d’UO2 pellets by ion implantation. The samples are then subjected to various heat (lien plateforme fours) or irradiation (lien chambre d’irr.) treatments (at room temperature or high temperature). Element concentration profiles are obtained by SIMS. In parallel, various characterizations (MET, EXAFS) are undertaken in order to characterize the chemical state of the elements (bubbles, metallic precipitates…) and the microstructural evolution of UO2 (Raman spectroscopy, DRX). Finally, the “diffusion mechanisms” aspect is mainly addressed through the use of atomic scale modelling, either by ab initio calculations (DFT) or by the use of empirical potentials (Molecular Dynamics).

1.2 Study of the ageing of boron carbide (B4C)

The structural integrity of boron carbide will rapidly degrade under neutron bombardment from the majority nuclear reaction 10B(n,4He)7Li. As helium is a gas, it rapidly forms bubbles and plays a major role in the premature ageing of ceramics. The behaviour of this element and the overall degradation of the material have been studied in particular by the theses of V. Motte (2014-2017) and G. Victor (2013-2016) which are the result of collaboration between the CEA and IP2I. The behaviour of lithium and tritium created by minor reactions is currently little studied. It is therefore important to be able to quantify their diffusive nature, if only for radiation protection purposes, and to assess their impact on helium behaviour in order to refine our understanding of the mechanisms of degradation of boron carbide by helium. These questions are currently being addressed in Mohand Bousseksou’s thesis, still based on a collaboration between CEA and IP2I.

Hexagonal structure of boron carbide (B11Cp)CBC modelled with VESTA software

On the other hand, in collaboration with the IRCER of Limoges, the ACE group is interested in the characterization of materials likely to replace boron carbide such as hafnium boride (HfB2) or a ternary phase BCO, to improve mechanical resistance. For the latter, the experimental part is largely supported by a theoretical part combining ab initio calculations to calculate the formation energy of all possible BCO structures and thermodynamic calculations using the Calphad method.

II. Tribocorrosion of metal alloys under irradiation

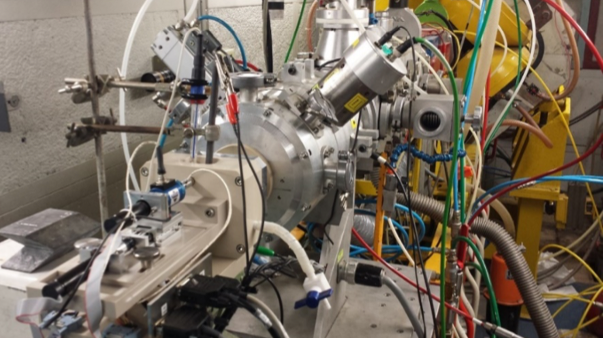

Since 2014, the ACE team, in collaboration with the CorrIs team of the MATEIS laboratory (INSA-Lyon), has been working on tribocorrosion under irradiation of 316L stainless steel. The aim of this research is to understand the possible synergies between friction, corrosion and irradiation on the evolution of the passive protective film that forms on the surface of the steel and acts as a corrosion barrier. The originality of this study is to have designed and developed an original tribocorrosimeter that can be adapted to several accelerators and that allows to study in-situ the evolution of the passive film thanks to on-line electrochemical measurements. Currently, the proton irradiation experiments are carried out at the cyclotron of CEMHTI, CNRS, Orleans, a platform of the EMIR&A research federation. This study is currently the subject of P. Martinet’s thesis.

Experimental device developed for the study of tribocorrosion under irradiation

III. Study of ionic liquids for the separation of actinides and lanthanides

Ionic liquids have remarkable properties that make it possible to envisage their use for radiochemical applications. Our objective is to study the chemical behaviour of lanthanides and actinides in order to propose new routes for their selective separation. Understanding the mechanisms and kinetics of solvent extraction requires the study of reactions at the liquid-liquid interface. The ANR PROfILE project “Probe the interface of an ionic liquid with water during extraction” started in 2018 for 48 months aims to understand at the microscopic level how the nature and structure of the interfaces evolve during the transfer of the ion from water to the ionic liquid phase, and to specify the underlying mechanisms. To achieve this, PROfILE combines nonlinear optical spectroscopy, extraction and surface tension studies, and molecular dynamics simulations. The precise content of the phases in equilibrium will be analysed by spectroscopy (EXAFS, Hyper-Rayleigh Scattering, Fluorescence, NMR, UV-vis), chemical analysis, and simulations.

This fundamental work is carried out by four complementary teams: ILM, CMC, IPHC et IP2I.

Our core skills are the implementation and processing of data from ion beam analysis (IBA and SIMS) as well as the implementation of irradiation experiments at particle accelerators. We also have expertise in spectroscopic characterization techniques (Raman, EXAFS, UV-Vis) and, to a lesser extent, microscopies (SEM, TEM). Finally, we carry out atomic scale modelling.

- I. Sample processing

- II. Measurement of the concentration of heavy or light elements in materials

- III. Characterisation of the physico-chemical or structural state of the material

- IV. Atomic scale modelling of materials

I. Sample processing

Our team has a platform of high-temperature furnaces allowing heat treatments of materials in a wide range of temperature (from 500 to 1600°C) and atmosphere (vacuum, neutral gas, reducing or oxidizing).

We have also designed a transportable experiment chamber allowing the irradiation of samples at high temperatures (up to 1000°C) on ion accelerators.

II. Measurement of the concentration of heavy or light elements in materials

Different techniques are used to carry out in-depth determination of the elements of interest in the materials studied: ion beam analysis (RBS, NRA, PIXE) and SIMS spectrometry.

III. Characterisation of the physico-chemical or structural state of the material

In order to characterize the chemical state of elements in solid or liquid samples, we use several spectroscopic techniques: X-ray absorption spectroscopy, Raman spectroscopy and UV-visible spectroscopy. In collaboration with various laboratories on university campus or national or even international, we also perform electron microscopy (SEM, TEM) to characterize the surface states of our samples and study the extensive defects of materials.

IV. Atomic scale modelling of materials

In support of the experimental part and thanks to the clusters of servers present on the university campus (CRAL, IP2I, ENS Lyon), we have acquired skills for modelling at the atomic scale, either by ab initio calculations (using DFT) or by using semi-empirical potentials allowing to perform temperature calculations via molecular dynamics. The information resulting from these calculations relate to the incorporation or defect energies in the structures studied, thus enabling the prediction of the best incorporation sites. We can also access mechanical properties (bulk modulus, elastic constants, mesh parameters) in temperature and predict for some elements their diffusion coefficients.

Varian Cary 100 UV-VIS spectrometer

Renishaw inVia Qontor confocal micro-Raman spectrometer ( = 405, 532, 633 nm)

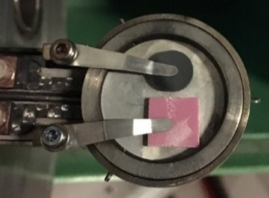

Sample holder

Thermal irradiation cell

Annealing assembly under moist oxidizing atmosphere (500-1000°C)

Our core skills are the implementation and processing of data from ion beam analysis (IBA and SIMS) as well as the implementation of irradiation experiments at particle accelerators. We also have expertise in spectroscopic characterization techniques (Raman, EXAFS, UV-Vis) and, to a lesser extent, microscopies (SEM, TEM). Finally, we carry out atomic scale modelling.

- I. Sample processing

- II. Measurement of the concentration of heavy or light elements in materials

- III. Characterisation of the physico-chemical or structural state of the material

- IV. Atomic scale modelling of materials

I. Sample processing

Our team has a platform of high-temperature furnaces allowing heat treatments of materials in a wide range of temperature (from 500 to 1600°C) and atmosphere (vacuum, neutral gas, reducing or oxidizing).

We have also designed a transportable experiment chamber allowing the irradiation of samples at high temperatures (up to 1000°C) on ion accelerators.

II. Measurement of the concentration of heavy or light elements in materials

Different techniques are used to carry out in-depth determination of the elements of interest in the materials studied: ion beam analysis (RBS, NRA, PIXE) and SIMS spectrometry.

III. Characterisation of the physico-chemical or structural state of the material

In order to characterize the chemical state of elements in solid or liquid samples, we use several spectroscopic techniques: X-ray absorption spectroscopy, Raman spectroscopy and UV-visible spectroscopy. In collaboration with various laboratories on university campus or national or even international, we also perform electron microscopy (SEM, TEM) to characterize the surface states of our samples and study the extensive defects of materials.

IV. Atomic scale modelling of materials

In support of the experimental part and thanks to the clusters of servers present on the university campus (CRAL, IP2I, ENS Lyon), we have acquired skills for modelling at the atomic scale, either by ab initio calculations (using DFT) or by using semi-empirical potentials allowing to perform temperature calculations via molecular dynamics. The information resulting from these calculations relate to the incorporation or defect energies in the structures studied, thus enabling the prediction of the best incorporation sites. We can also access mechanical properties (bulk modulus, elastic constants, mesh parameters) in temperature and predict for some elements their diffusion coefficients.

Varian Cary 100 UV-VIS spectrometer

Renishaw inVia Qontor confocal micro-Raman spectrometer ( = 405, 532, 633 nm)

Sample holder

Thermal irradiation cell

Annealing assembly under moist oxidizing atmosphere (500-1000°C)

NON-PERMANENTS:

- DOCTORANTS / DOCTORAL STUDENTS:

- Théo Roubille, Roland Ducher, Robert Tétot, Nicolas Salles, Yves Pipon. Diffusion studies in UO2 with an improved tight-binding potential: SMTB-QB. Acta Materialia, 2026, 303, pp.121750. ⟨10.1016/j.actamat.2025.121750⟩. ⟨hal-05381035⟩

- Jean-Marc Costantini, Aurélien Canizares, Patrick Simon, Christel Laberty-Robert, Gérald Lelong, et al.. Irradiation response during the early stages of alpha radiation damage in mesoporous nanocrystalline ceria films. Acta Materialia, 2026, 306, pp.121944. ⟨10.1016/j.actamat.2026.121944⟩. ⟨hal-05485998⟩

- Fouad Bentata, Arnaud Taute, Capucine Laprais, Régis Orobtchouk, Eva Kempf, et al.. Spatially-Controlled Planar Guided Crystallization of Low-Loss Phase Change Materials for Programmable Photonics. Adv.Mater., 2026, 38 (8), pp.e06609. ⟨10.1002/adma.202506609⟩. ⟨hal-05059864⟩

- Antonin de Azevedo. Influence du dopage au chrome du combustible UO2 sur la spéciation des produits de fission en conditions accidentelles. Matériaux. Université Claude Bernard - Lyon I, 2025. Français. ⟨NNT : 2025LYO10214⟩. ⟨tel-05445945⟩

- Antonin de Azevedo, Fabienne Audubert, Nathalie Moncoffre. Identification of grain growth mechanisms during the sintering of Cr-doped UO2. ECerS XIX, Aug 2025, Dresden, Germany. ⟨cea-04911654⟩

- Théo Roubille. Etude théorique de la microstructure et du comportement des produits de fission dans le combustible d’oxyde d’uranium dopé à l’oxyde de chrome. Physique Nucléaire Théorique [nucl-th]. Université Claude Bernard - Lyon I, 2024. Français. ⟨NNT : 2024LYO10355⟩. ⟨tel-04966272⟩

- C. Gaillard, H. Lotz, L. Sarrasin, Y. Pipon, Roland Ducher, et al.. Insights on the UO2+x/U4O9 phase characterization in oxidized UO2 pellets as a function of the hyper-stoichiometry. Frontiers in Nuclear Engineering, 2024, 3, pp.1465080. ⟨10.3389/fnuen.2024.1465080⟩. ⟨hal-04780928v2⟩

- T. Roubille, R. Ducher, R. Tétot, Y. Pipon. Fission product diffusion in chromium doped UO

by means of a new variable-charge interatomic potential. NuMat 2024: The Nuclear Materials Conference, Oct 2024, Singapore, Malaysia. ⟨in2p3-04951211⟩

by means of a new variable-charge interatomic potential. NuMat 2024: The Nuclear Materials Conference, Oct 2024, Singapore, Malaysia. ⟨in2p3-04951211⟩ - G. Gutierrez, N. Moncoffre, Y. Pipon, D. Gosset, N. Djourelov, et al.. Irradiation-induced diffusion of lithium implanted in boron carbide. NuMat 2024: The Nuclear Materials Conference, Oct 2024, Singapore, Malaysia. ⟨in2p3-04951074⟩

- Théo Roubille, Roland Ducher, Robert Tétot, Yves Pipon. Study of chromium doped UO2 as advanced technology fuels by means of a new variable-charge interatomic potential. TopFuel 2024, ENS (European Nuclear Society); American Nuclear Society (ANS); Chinese Nuclear Society(CNS); Korean Nuclear Society (KNS), Sep 2024, Grenoble, France. ⟨hal-05074728⟩