The Ion Beam department is in charge of the maintenance, operation and development of the IP2I particle gas pedals.

Ion beams are used by various scientific teams in the laboratory. Depending on their energy and nature, these beams can be used to pulverize matter, analyze an atomic composition, implant ions into materials or test their behavior under the effect of certain radiations (modification of the chemical structure, degradation…). These activities are carried out at IP2I in collaboration with the research teams Nuclear energy, Nanodroplets.

In addition to research activities, we maintain and develop beamlines and equipment associated with particle gas pedals. We also ensure the development and design of beam acceleration platforms to meet the future needs of IP2I research groups or national projects.

The Ion Beam department also makes its facilities available for teaching purposes and public visits.

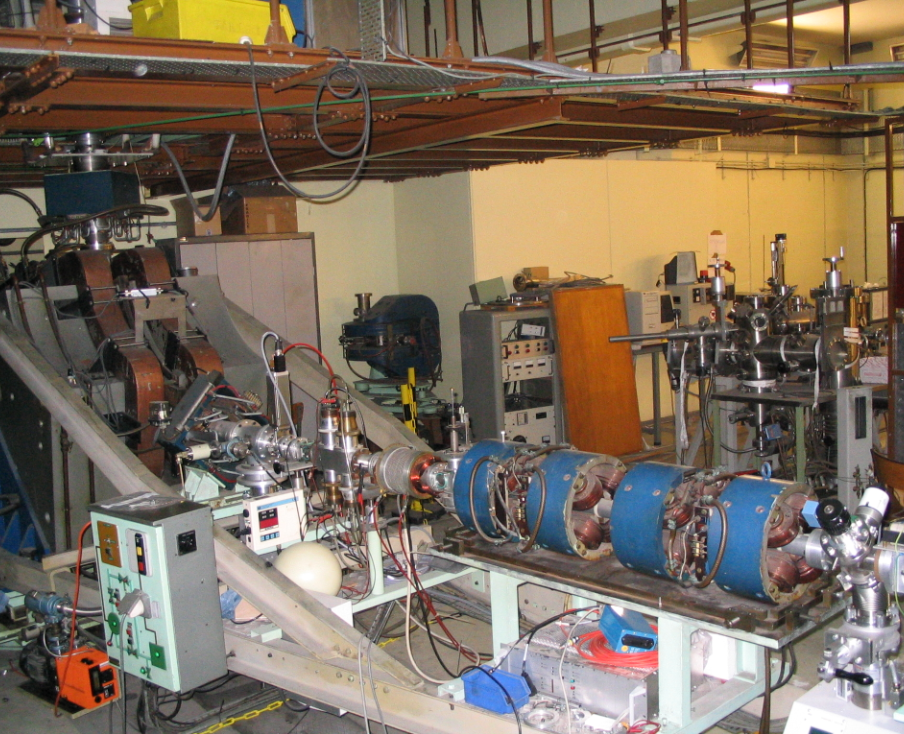

The IP2I has 3 particle accelerators :

- A Van De Graaf 4 MV type electrostatic accelerator with several beam paths for ion beam analysis and irradiation.

- A 400 kV electrostatic accelerator for ion implantation (IMIO400).

- A complex of accelerators dedicated to the research work of the IPM group on which the department has technical responsibility for maintenance and development.

Ion beam analysis of samples

These analyses are done at the different beam paths of the Van de Graaff 4 MV. The analysis techniques used (RBS, PIXE, ERDA, Nuclear Reaction Analysis) allow to characterize the composition of the samples.

Ion implantation

Ion implantation consists of inserting a certain amount of material into any sample at a chosen depth. This depth depends on the physico-chemical properties of the material but also on the energy of the accelerated ions and their electrical charge.

Thus, the 400 kV implanter makes it possible to implant a wide variety of ions at an energy that varies from 5 MeV to 5 MeV depending on the charge. The installation ranges from 60 keV to 800 keV depending on the ions. An electrostatic scanning device allows sample areas of up to 80 cm².

The Van de Graaff 4 MV gas pedal allows the implantation of ions (proton, helium deuton) from 0.9 to 7.tion. An electrostatic scanning device allows the simultaneous and homogeneous implantation of a maximum surface of about 6 cm2.

In both cases, the implanted dose is generally between 1.1012 and 1.1017 ions/cm².

Support for experiments on our machines

We provide technical assistance to research groups operating on our beamlines in various fields: vacuum, electromechanics, electronics, mechanics…

This has recently resulted in the realization of a multi-analysis chamber on the Van de Graaff 4 MV or the Radiograaff biological irradiation line.

Study and development of ion acceleration platforms

We are participating in the design of the Ganil Spiral2 ion source.

Renovation of the installations; upgrading to safety standards

All the members of the department participate in the renovation of the machines as well as in their compliance, particularly in terms of safety. We are subject to ASN authorization.

Thus, we realized the automation of the Van de Graaff 4 MV and its beam paths.

On IMIO400, the control-command has been completely rethought and a new automated implantation chamber is being installed.

ABBOU Natanel

ABDOUL-CARIME Hassan

ABREU AGUILAR Henso Javier

ALBERT Sébastien

ALCOCER AVILA Mario

ALEZRAA Timothé

ALPHONSE Gersende

AMRAM David

ARBEY Alexandre

ARMATOL Antoine

ARNAUD Nicolas

AUFRANC Cecile

AUGIER Corinne

AUTIERO Dario

AZAM Clémentine

BALLEYGUIER Loup

BARTHELEMY Eleonore

BAULIEU Guillaume

BECHETOILLE Edouard

BENDER Michael

BENECH Eric

BENNACEUR Karim

BENOIT Alain

BENTARA Ines

BERERD Nicolas

BERTHET Frédéric

BEUVE Michaël

BILLARD Julien

BONNEVAUX Alain

BORJA Caroline

BOUAFIF Chaima

BOUAZIZ Benjamin

BOUDON Alexis

BOUDOUL Gaelle

BOUHELAL Malik

BOUTE Maxime

BOVON Alfred

BUTHOD Anthony

CALABRIA Peter

CAPOANI Lionel

CAPONETTO Luigi

CARLE Aurélien

CARLUS Bruno

CAZES Antoine

CERUSE Philippe

CHAIZE David

CHANFRAY Guy

CHANON Nicolas

CHARLIEUX Florence

CHAUVET Clément

CHEN Xiushan

CHESHKOV Cvetan Valeriev

CHOI Ji-Eun

COLAS Jules

COMBARET Christophe

CONSEIL Simon

CONTARDO Didier

COPIN Yannick

COULON Matthieu

COURTOIS Helene

CUZON Stephane

DAHOUMANE Mokrane

DALLALI Wajdi

DANIEL Jessy

DARME Luc

DAVESNE Dany

DAVID Quentin

DAVIDSON Sacha

DE AZEVEDO Antonin

DE JESUS Maryvonne

DE LAURETIS Ginevra

DEANDREA Aldo

DEGALLAIX Jerome

DELAUNAY Didier

DELLA NEGRA Rodolphe

DEPASSE Pierre

DHANMEHER Karishma

DOIZON Fabien

DOSSOU Jean-Michel

DUCIMETIERE David

DUCOIN Camille

DUDOUET Jérémie

DUPASQUIER Thierry

EALET Anne

EL MAMOUNI Houmani

EL MECHERFI Oussama

ERICSON Magda

EYNARD Alexis

FARDEAU Niels

FARIZON Bernadette

FARIZON Michel

FAY Jean

FERRIOL Sylvain

FILLAUDEAU Enzo

FILLOL Raphael

FILOCHE Baptiste

FLORES Sylvie

FONTAINE Christine

FOREST Daniele

FRANCE Jade

GAILLARD Clotilde

GAILLARD Déborah

GALBIT Geoffrey

GALYMOV Vyacheslav

GANOT Constance

GARAH Djamila

GARDE Gustave

GARILLOT Guillaume

GASCON Jules

GASCON Susan

GAVARINI Stéphane

GERMANI Lionel

GIERES François

GIRAUD Yoan

GONCALVES LARBI Sandra

GOUZEVITCH Maxime

GRANATA Massimo

GRENIER Gerald

GUERIN Cyrille

GUILLON Valentin

HAEGEL Leïla

HANSEN Hubert

HOFMAN David

HOHENEGGER Stefan

IANIGRO Jean Christophe

ISNARD Wanda

JACMART-GAMBUT Florence

JOSHI Sachin

JOUBERT Gaspard

JOURD'HUY Élise

JUILLARD Alexandre

KUBIK Bogna

LACHUER Quentin

LACROIX Leander

LAGRANGE Bernard

LAKTINEH Imad

LALLE Philippe

LARAVINE Anthony

LARBI Mehdi

LARGER Frédéric

LATHUILIERE Brice

LE BELLEC Tatiana

LE JEAN Maxime

LEBRUN Patrice

LENGYEL Jozef

LETHUILLIER Morgan

LISSILLOUR Hector

LOPEZ Jean Pierre

LORIT Victor

LOTTEAU Clément

MAATALLAH Laïla

MACABIAU Clara

MAGNE Nicolas

MAGNIN Jérôme

MAHMOUDI Farvah

MALESYS Céline

MARCHISONE Massimiliano

MARK Maximilian

MARTEAU Jacques

MARTINI Nicolas

MASSOTEAU Benjamin

MATHEZ Herve

MAUCERI Giorgio

MERENI Lorenzo

MEYER Jacques

MICHEL Christophe

MILLARD-PINARD Nathalie

MIRABITO Laurent

MISHRA Dayanand Kishan Kumar

MONCOFFRE Nathalie

MOUNIER Franck

NADJI Séverin

NEDELEC Patrick

NESHATPOUR Siavash

NODARI Benedetta

NOEL Guillaume

NORTIER Florian

NTAGANZWA Uwimana Jules

OUAZANI Youssouf

OUZRIAT Amazigh

PARRADO Laura

PASQUIER Tanguy

PENNACCHIO AUTIERO Elisabetta

PERRIES Stéphane

PHILOUZE Pierre

PINARD Laurent

PIPON Yves

POLI PANTELIS Bruno

POPOVIC Brodie

PRADHAN Bikram Keshari

PUGNERE Denis

PUROHIT Arnab

RAMASUBRAMANIAN Niveditha

REDON Nadine

REYMERMIER Théo

RICHARD Jean-Marc

RIGAULT Mickaël

RIOU Laurent

RODRIGUEZ-LAFRASSE Claire

RULLIERE Alain

RUPPIN Florian

RUSSO Patrice

SAADE Gaëlle

SABRA Karim

SANGLARD Véronique

SASSOLAS Benoit

SAYAH Sihem

SCHIBLER Emilie

SCHIRRA Florent

SEROUR Karim

SMADJA Gerard

SORDINI Viola

SOTO Charles

STEZOWSKI Olivier

STRUBBIA MANGIARELLI Camila

TBATOU Saïd

TEILLON Julien

TESTA Etienne

TISSOT Mathilde

TRAMONTINI Matias

TROMEUR William

TSIMPIS Dimitrios

URAS Antonio

VAGINAY William

VANDER DONCKT Muriel

VAROCLIER Virginie

VERDIER Patrice

VEROLLET Christian

VERZEROLI Mattia

VINCENEUX Romain

VIRET Sebastien

VITTAZ Paul

WOZNY Anne-Sophie

XIAO Jie

XU Lang

ZIMMERMANN Léo

ZOCCARATO Yannick